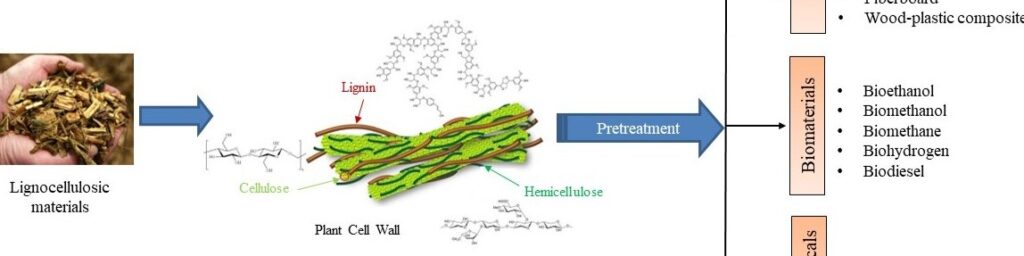

Lignocelluse Based Biorefinery

Focusing on the sustainable use of resources, at the Department of Chemical, Polymer & Composite Materials Engineering, we develop and optimise multifunctional lignocellulosic based composite materials for structural and construction industries. These products and materials are sourced from bio-based materials such as wood and other renewable raw materials. We use our knowledge of these raw materials to help us find innovative products. In our work, we place particular emphasis on extraction of high quality fiber and product quality.

We focus on the following research areas in particular:

· Composite materials

· Biodegradable polymer resin

· Pretreatment of agricultural waste to produce high quality fibers

Research Projects

- “The future is garbage: Reusing of plastics for integrated reduction of carbon footprints and sustainable development of materials for structural applications”, National Research Program for Universities (NRPU), Higher Education Commission, Pakistan (Awarded April 2022) (Funding Rs. 7.1 Million)

- “Ionic liquids assisted extraction of cellulose-rich fiber (CRF) from agro-industrial waste to manufacture biocomposite panels”, National Research Program for Universities (NRPU), Higher Education Commission, Pakistan (Awarded March 2019) (Funding Rs. 5.5 Million)

“Fabrication of green fiberboard panels through ionic liquids mediated processing of agricultural waste”, Faculty Research Proposal Grant (FRGP), University of Engineering & Technology, Lahore, Pakistan (Awarded Feb 2019) (Funding Rs. 1.2 Million)

“Ionic liquid assisted extraction of cellulosic fiber from agricultural waste to manufacture fiberboard” Start-up Research Grant for fresh PhDs-2017, Higher Education Commission (HEC), Pakistan. (Awarded Oct 2017) (Funding Rs. 0.5 Million)

Research opportunities

Undergraduate and postgraduate students can contact for research project opportunities

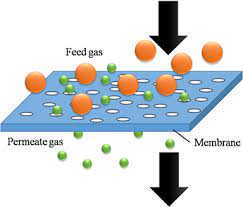

Membrane Based Separations

Membrane-based separations have emerged as a versatile and efficient technology with widespread applications in various industries, addressing the increasing demand for precision separation processes. These separations rely on the selective permeability of thin membranes to separate different components from a fluid mixture based on their size, shape, or chemical properties. The concept of membrane separation encompasses diverse techniques such as ultrafiltration, microfiltration, nanofiltration, and reverse osmosis.

As we delve deeper into the intricacies of membrane technology, we uncover its potential to revolutionize separation processes and contribute to a more efficient and eco-friendly future.

- 1)“Prototype development of novel polymeric blend hollow fiber membranes for biogas enrichment”

Funding Amount: 9.56 MPKR, Sponsor: NRPU, HEC Islamabad, Pakistan

2) “Polymeric blend membranes for methane enrichment”

Funding Amount: Amount: 1.02 M Riyal, Sponsor: Deanship of Scientific Research, University of Jeddah, Saudi Arabia

3) “Enhancing CO2 Gas Separation through optimization of Performance Parameters of Polymeric Membranes”

Funding Amount: 10 K Riyal, Sponsor: Deanship of Scientific Research, University of Jeddah, Saudi Arabia

Contact Person

Dr. Asif Jamil

Assistant Professor

Department of Chemical, Polymer and Composite Materials Engineering

UET-Lahore (New Campus)

[email protected]

Liquid Crystal Polymers

LCPs belong to a special class of materials that lie between a solid and liquid composition (a unique state of matter called a ‘mesophase’).